What is a Screw Machine, and How Does it Work?

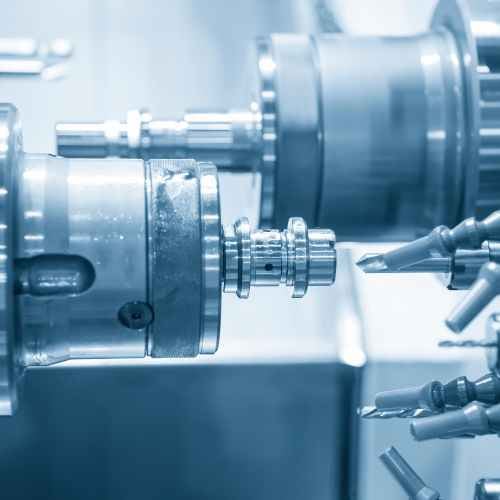

Screw machines are a type of automatic lathe used in various industries, including manufacturing and automotive.

These machines are designed to produce high volumes of precision parts quickly and efficiently.

In this guide, we'll look closer at how screw machines work, their advantages, and the different types of screw machines available.

.jpg?width=750&height=422&name=screw%20machine_iso%20certified_blue%20chip%20engineered%20products%20(1600%20%C3%97%20900%20px).jpg)

Introduction to Screw Machines.

Screw machines are a type of automatic lathe that is used to produce high volumes of precision parts quickly and efficiently.

These machines are commonly used in manufacturing, automotive, and aerospace industries.

They are designed to perform a variety of operations, including drilling, tapping, and threading, and can produce parts with tight tolerances and complex geometries.

In this guide, we'll explore the basics of screw machines, including how they work and their advantages.

Types of Screw Machines.

There are several types of screw machines, each with its own unique features and capabilities. Some of the most common types include single-spindle screw machines, multi-spindle screw machines, and Swiss-style screw machines.

Single-spindle machines are ideal for producing small to medium-sized parts, while multi-spindle machines are better suited for high-volume production of smaller parts.

Swiss-style machines are known for their ability to produce complex parts with high precision.

Understanding the different types of screw machines can help you choose the right one for your specific application.

How Screw Machines Work.

Screw machines are automated machines that are used to produce large quantities of small to medium-sized parts.

They work by feeding a bar of material into the machine, which is then clamped in place and rotated at high speeds. As the bar rotates, cutting tools are used to shape and form the material into the desired shape.

The finished parts are then ejected from the machine and collected for further processing or assembly.

Screw machines are known for their high production rates, accuracy, and repeatability, making them popular in many industries.

Advantages of Screw Machines.

Screw machines offer several advantages over other manufacturing methods. One of the biggest advantages is their high production rates.

Screw machines can produce large quantities of parts quickly and efficiently, making them ideal for high-volume production runs. They also offer excellent accuracy and repeatability, ensuring that each part is identical to the next.

Additionally, screw machines can work with a wide range of materials, including metals, plastics, and composites, making them versatile machines for many applications.

Applications of Screw Machines.

Screw machines are used in a variety of industries, including manufacturing, automotive, aerospace, and medical.

They are commonly used to produce small to medium-sized parts, such as screws, bolts, and fittings. In the automotive industry, screw machines are used to produce engine components, while in the medical industry, they are used to produce surgical instruments.

Screw machines are also used in the production of electronics, appliances, and toys. With their high production rates and accuracy, screw machines are a valuable tool for many applications.

Screw machines are utilized to manufacture fasteners and components that secure or join two or more objects together. These fasteners are specifically designed to be used with screw machines, which are automatic lathes used for high-volume production of small parts.

Common fasteners manufactured using screw machines include screws, nuts, bolts, and washers. These fasteners are typically made from metal, such as steel, brass, or aluminum, and come in a range of sizes and shapes.