The Eco-Friendly Benefits of Cold-Headed Fasteners

In the modern era, sustainable manufacturing has become a pivotal focus for industries worldwide. Engineers, as the driving force behind this shift, are increasingly tasked with finding solutions that meet production demands and minimize environmental impact. Cold-headed fasteners emerge as a critical component in this quest for sustainability.

What Are Cold Headed Fasteners?

Manufacturing Cold-headed fasteners involves forming metal at room temperature rather than cutting or machined. This technique results in stronger and more durable fasteners, ideal for various applications.

Environmental Benefits of Cold-Headed Fasteners

Reduced Material Waste

Cold heading is a near-net-shape process, producing less waste than traditional machining methods. This efficiency in material usage reduces the cost and conserves resources, aligning with sustainable manufacturing goals.

Energy Efficiency

The cold heading process requires significantly less energy than other manufacturing techniques, such as hot forging or machining. By reducing energy consumption, cold-headed fasteners contribute to a lower carbon footprint, making them an environmentally friendly choice for engineers.

Lower Carbon Footprint

Cold-headed fasteners significantly lower their carbon footprint by reducing material waste and enhancing energy efficiency, making them a sustainable choice for industries aiming to reduce environmental impact.

Applications of Cold-Headed Fasteners in Sustainable Manufacturing

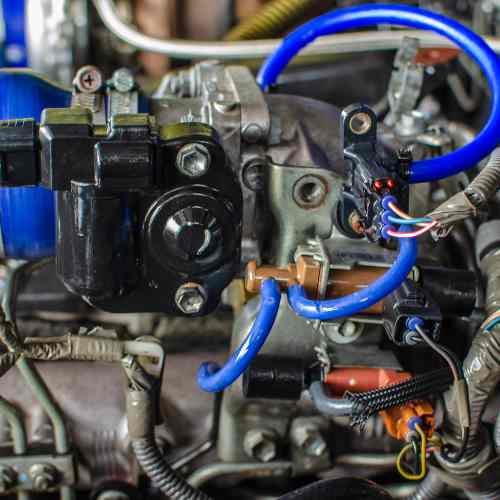

Automotive Industry

Manufacturers extensively use cold-headed fasteners in the automotive sector, particularly for producing lightweight and fuel-efficient vehicles. Their strength and durability make them ideal for critical applications, contributing to the overall sustainability of automotive manufacturing.

Renewable Energy Sector

In the renewable energy sector, cold-headed fasteners play a crucial role in the assembly of wind turbines and solar panels. Their reliability and longevity ensure the durability of these installations, supporting the growth of sustainable energy solutions.

Construction and Infrastructure

The use of cold-headed fasteners enhances eco-friendly building practices in the construction industry. Their application in sustainable construction projects enhances the durability and reduces the environmental impact of infrastructure development.

Cold-headed fasteners provide a sustainable solution for engineers seeking to reduce environmental impact while maintaining high performance and reliability. Industries can move towards more sustainable practices by integrating these fasteners into manufacturing processes.

Engineers and manufacturers are encouraged to explore the benefits of cold-headed fasteners in their projects. Adopting these eco-friendly components can contribute to a more sustainable future in manufacturing. This blog post aims to inform engineers about the significant environmental benefits of using cold-headed fasteners in various industries.

By focusing on sustainability, engineers can lead the way in reducing the environmental impact of manufacturing processes, fostering a sense of curiosity and open-mindedness.