Specialty Fasteners: Sealing Fasteners Enhance Equipment Performance

Sealing fasteners play a vital yet often overlooked role in safeguarding various equipment and devices in modern industries. From electrical enclosures and medical devices to automotive valves, pneumatic and hydraulic equipment, electric vehicle charging units, HVAC systems, robots, sensors, and pumps, sealing fasteners ensure these components remain resilient against exposure to many potential hazards.

We will explore the significance of sealing fasteners in protecting our machinery from external contaminants and extreme conditions and their role in preventing environmental pollution.

Guardians of Protection | Sealing Fasteners

-

Protection from External Contaminants

Sealing fasteners act as invisible shields, fortifying equipment against various external threats. These fasteners are designed to keep oil, gases, liquids, chemicals, dust, dirt, moisture, and even saltwater at bay, shielding the internal components from harm. In medical devices, for instance, sealing fasteners ensure that delicate electronic elements remain sterile and uncontaminated, which is vital in critical healthcare scenarios.

-

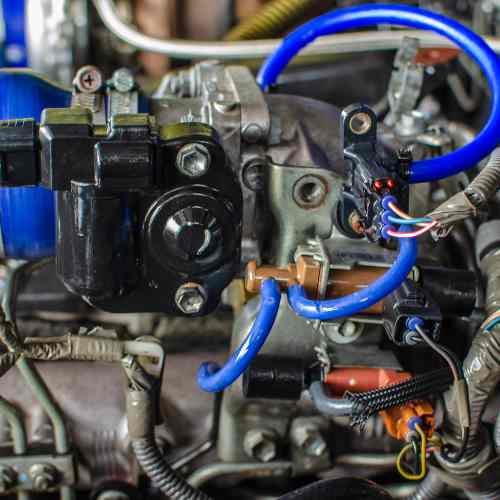

Resistance to Extreme Conditions

Equipment operating under harsh conditions requires unwavering protection. Sealing fasteners come to the rescue by providing resistance against extreme pressure, temperature, and weather conditions. In automotive valves, for example, these fasteners guarantee the longevity and reliability of the valves, even in high-temperature environments where precision is crucial for optimal engine performance.

-

Pollution Prevention

In an era of environmental preservation, sealing fasteners minimize pollution by preventing the seepage of harmful pollutants into the surroundings. Industries such as oil and gas heavily rely on sealing fasteners to ensure that leaks do not occur, mitigating the risk of toxic substances contaminating ecosystems.

Sealing Fasteners Applications Across Industries

.jpg?width=500&height=500&name=markets%20served_electronic%20hardware_blue%20chip%20engineered%20products%20(500%20%C3%97%20500%20px).jpg)

-

Electrical Enclosures

Electrical enclosures house sensitive electronic components and mechanisms. Sealing fasteners in these enclosures ensure that electrical circuits and connections are safeguarded from moisture, dust, and other contaminants, preventing short circuits and system failures.

-

Medical Devices

The medical industry relies on precision and sterility in its devices. Sealing fasteners are crucial in maintaining a clean and safe environment within medical equipment, vital for accurate diagnosis and patient safety.

-

Automotive Valves

In the automotive sector, sealing fasteners secure valves, ensuring efficient engine performance and emission control. These fasteners prevent the infiltration of harmful substances and contaminants that could otherwise damage the engine.

-

Pneumatic and Hydraulic Equipment

Sealing fasteners are indispensable for pneumatic and hydraulic equipment, as they protect against leaks, ensuring optimal performance and safety in critical systems like brakes and power steering.

-

Electrical Vehicle Charging Units

Sealing fasteners guarantee the safe and efficient operation of electric vehicle charging units, safeguarding sensitive electronic components from environmental exposure and damage.

-

HVAC Systems

Heating, Ventilation, and Air Conditioning (HVAC) systems often operate under varying weather conditions. Sealing fasteners are essential in maintaining the efficiency and longevity of these systems, preventing any external elements from compromising their performance.

-

Robots and Sensors

In robotics and sensor applications, precision and reliability are crucial. Sealing fasteners protect the delicate internal components of robots and sensors from harsh environments, ensuring accurate data collection and dependable robotic operations.

-

Pumps

Pumps are widely used across industries for fluid transportation. Sealing fasteners in pumps safeguard against leakage, ensuring smooth and consistent operation and preventing potential environmental hazards.

While often hidden from sight, sealing fasteners are the unsung heroes that protect our equipment and devices from external threats. From enabling medical devices to save lives to ensuring the reliable operation of automotive valves and electrical enclosures, these fasteners play an instrumental role in enhancing performance and preserving the environment.

As industries continue to advance, the importance of investing in high-quality sealing fasteners becomes increasingly evident, ensuring that our machinery remains safeguarded and efficient for years to come.