Selecting the Right Specialty Fastener Supplier

Selecting the Right Specialty Fastener Supplier: A Comprehensive Guide

In the manufacturing world, having a reliable and efficient supply chain is paramount. This is particularly true regarding specialty fasteners - the small components that hold together the big pieces in various industries. Selecting the right specialty fastener supplier can be a game-changer for your production process. In this article, we'll explore the key factors you should consider when choosing a supplier for your specialty fastener needs, including the importance of ISO9001 certification, print-to-part capabilities, kitting and packaging, and vendor-managed inventory.

-

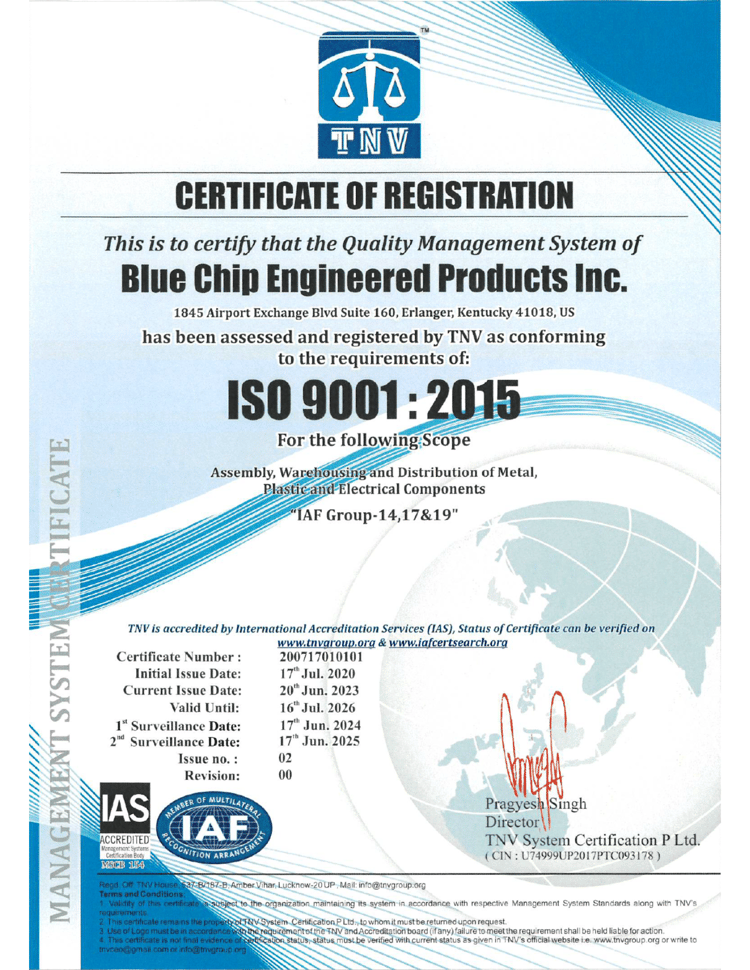

ISO 9001 Certification: The Quality Assurance Benchmark

When searching for a specialty fastener supplier, one of the first things you should look for is ISO 9001 certification. ISO 9001 is an international standard for quality management systems, and a supplier who has this certification demonstrates a commitment to maintaining high-quality standards in their production and management processes. ISO 9001 certification assures you that the supplier adheres to strict quality control protocols, ensuring that the fasteners you receive are consistent.

ISO 9001 certification signifies a commitment to continuous improvement, which means the supplier is likely to stay updated with the latest advancements in fastener technology, ensuring that your products are manufactured with the highest quality.

-

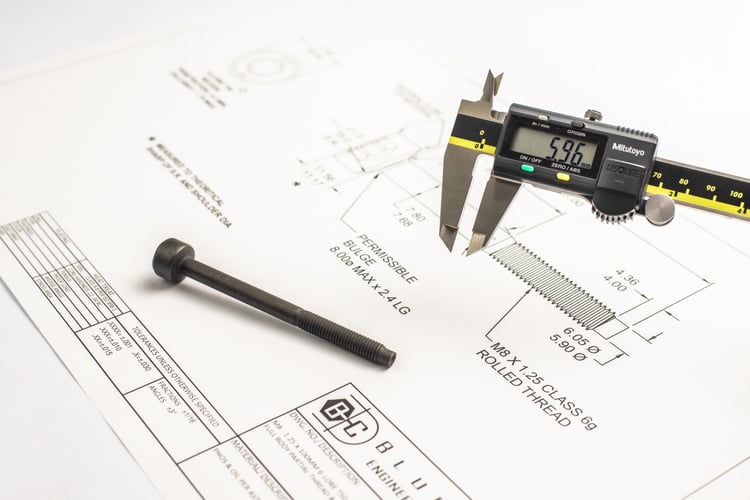

Print-to-Part Capabilities: Custom Solutions for Your Needs

In the manufacturing world, one size does not fit all. Your production processes and end products are unique, so your fasteners should meet your specific requirements. A supplier with print-to-part capabilities can work with you to design and manufacture fasteners that perfectly match your requirements.

These capabilities allow for size, material, and design customization, leading to better performance and cost efficiency in your production. Look for a supplier who can collaborate to create bespoke fasteners that optimize your processes and products.

-

Kitting and Packaging: Streamlining Your Operations

Kitting and packaging services from your fastener supplier can significantly enhance production efficiency. Kitting involves grouping related fasteners, making it easier for your assembly teams to access the right components quickly. Proper packaging ensures that the fasteners arrive at your facility in pristine condition, reducing the risk of damage or contamination.

Efficient kitting and packaging can minimize the time and effort required to locate and handle the fasteners, ultimately improving your productivity and reducing downtime on the production line. Discuss kitting and packaging options with prospective suppliers to ensure they meet your requirements.

-

Vendor-Managed Inventory: A Hassle-Free Approach

Maintaining an optimal inventory of specialty fasteners can be complex and time-consuming. Vendor-managed inventory (VMI) is a service offered by some specialty fastener suppliers that simplifies this process. With VMI, the supplier manages your fastener inventory, ensuring you have the right quantities when needed.

VMI can help you reduce carrying costs, eliminate out-of-stock situations, and minimize the administrative burden of tracking inventory levels. It's a strategic partnership that can streamline operations and reduce overall costs.

Selecting a specialty fastener supplier is a crucial decision impacting your production processes and bottom line. The importance of ISO 9001 certification, print-to-part capabilities, kitting and packaging services, and vendor-managed inventory must be considered.

By carefully considering these factors and choosing a supplier that aligns with your specific needs, you can optimize your supply chain and enhance the overall efficiency of your manufacturing operations.

So, don't rush the decision; take the time to find the right partner for your specialty fastener needs.