Cold heading is the process of forming metal into a predetermined shape by compressing it between two dies at room temperature.

This method offers many advantages over other metal working processes, including increased strength, better performance and cost savings.

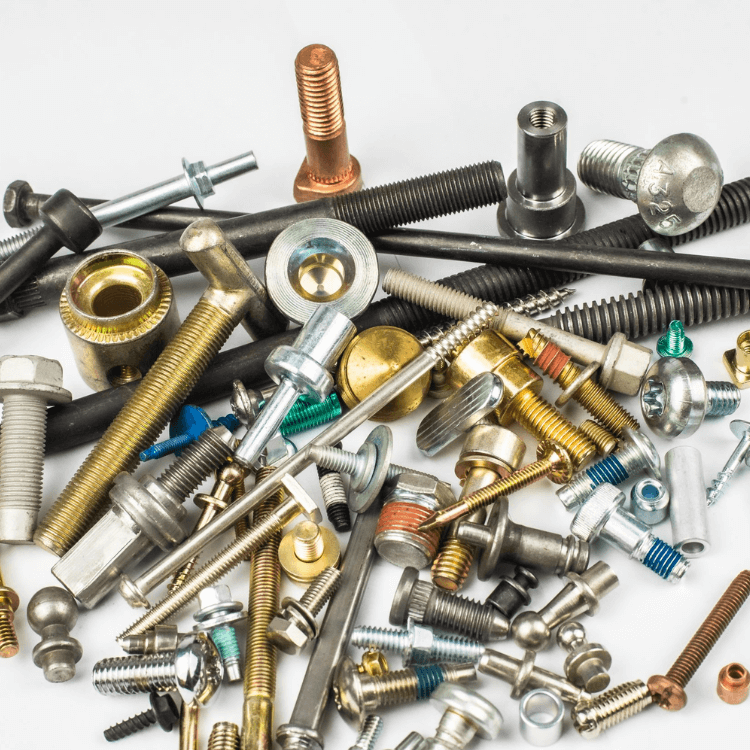

Types of Cold Heading Materials

Cold heading has been shown to work well with soft, low-carbon steel, stainless steel, copper alloys and brass alloys.

Each material has its own unique properties that contribute to the overall performance of the end product.

Soft, mild or low-carbon steel is often used for smaller items such as pins and rivets because it is relatively easy to shape without sacrificing structural integrity.

Copper alloys and brass alloys, as well as stainless are resistant to corrosion and long lasting in both indoor and outdoor environments.

Precision & Accuracy of Cold Heading

Cold heading offers more precision and accuracy than other methods because machines are programmed to move the material in a precise manner until the desired shape is achieved.

This ensures that all parts have uniform shape, size and strength.

Cold forming also helps improve the surface finish of components, making it suitable for applications with aesthetic requirements.

Cold heading also provides better tolerances than other processes, requiring less finishing work and resulting in cost savings.

Design Considerations & Customization Benefits

Cold heading provides the ability to create complex designs with intricate shapes.

While components produced via cold forming may vary in size, manufacturers can customize their parts more intricately by taking advantage of cold forming’s precision capabilities. This allows them to create components with unique shapes and features that match specific requirements.

Quality Assurance & Testing Enforcement

Quality assurance and testing enforcement are also important benefits of cold heading. With this type of manufacturing, the components produced can be closely inspected during the process to ensure they meet all requirements and perform correctly.

This includes rigorous visual inspections and metallurgical tests, such as tensile strength, hardness, and corrosion resistance.

By ensuring that all components are held to the highest quality standards each step of the way, cold heading can help manufacturers develop reliable products that are built to last.

Cost Savings Through Cold Heading Processes

Another great benefit of cold-heading materials is the cost savings they can provide.

In addition to reducing labor costs associated with machining operations, cold heading also offers great savings in tooling costs.

The dies used are typically built to last many thousands of cycles and require minimal maintenance over their lifetime. By using these dies, manufacturers can save money on maintenance, repair, and replacement costs for new custom parts or tooling sets.

%20(1)-1.jpg?width=750&height=422&name=what%20is%20cold%20forming%20for%20fasteners_%20blue%20chip%20engineered%20products%20(1600%20%C3%97%20900%20px)%20(1)-1.jpg)

.jpg?width=500&height=500&name=from%20print%20to%20part_%20blue%20chip%20engineered%20products%20(2).jpg)